The 5-section 47m rounded boom is made of high tensile steel, which allows for decreased boom weight as well as increased boom strength.

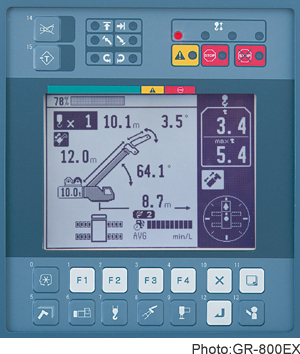

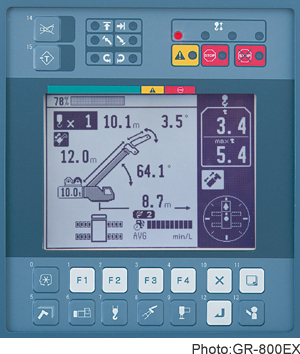

Tadano’s new AML-C is easy to use. It allows the operator to simultaneously monitor: boom angle, boom length, operating pressure of elevating cylinder, the extended width of the outriggers, slewing position, rated lifting capacity and present hook weight. All of this enables the AML-C to move easily through lifting capacity changes without changing configurations and codes to make a lift.

When operating the crane with the asymmetric outriggers extended, the AML-C automatically detects the extension width of outriggers at the front and rear, and to the left and right of the crane to offer maximum work value through each area. When slewing the boom from the longer outrigger area to the shorter outrigger area, the AML-C automatically detects the motion and displays the maximum capacity depending on each extension width of the outriggers, and brings the motion to a slow stop before it reaches the limits of the allowed capacity. Therefore, even if the operator operates the crane without being aware of a change in the capacity, the AML-C monitors it continuously to ensure safe operation.

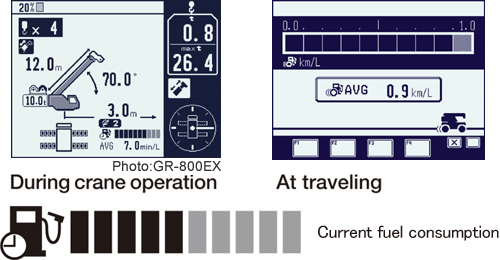

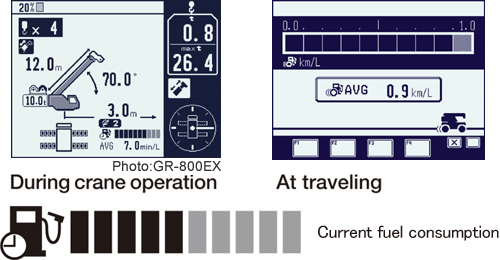

The system constantly monitors and displays on the AML screen information on fuel consuming conditions. Checking the indicator enables you to prevent wasteful acceleration and wasteful standby.

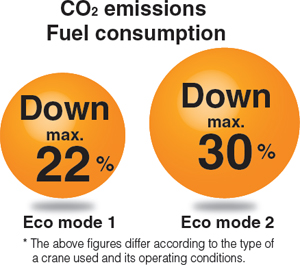

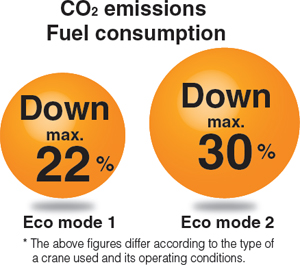

The system controls the maximum engine speed during crane operation. In addition, due to curbing an unnecessary rise in the engine speed that occurs when accelerated to excess, the system enables CO2 emissions and fuel consumption to decrease by max. 22% with the Eco mode 1 employed, and max. 30% when the Eco mode 2 is applied. In addition, it realizes a low level of noise.

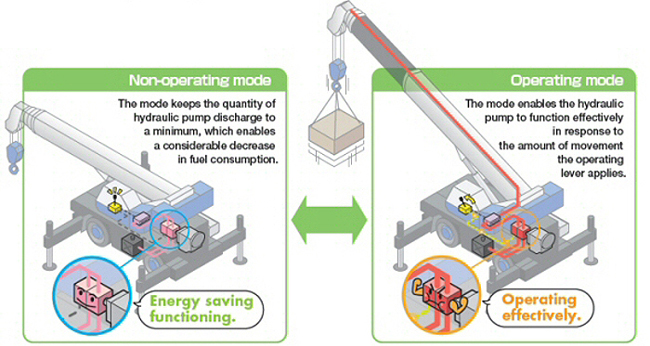

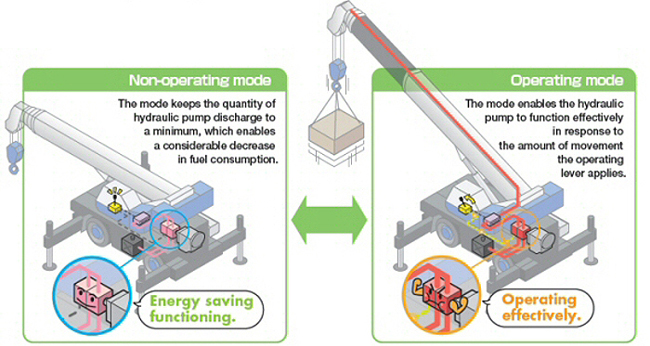

The system effectively controls the quantity of hydraulic pump discharge at the time of crane operation in response to the amount of movement applied by the operating lever. Additionally, it keeps the quantity of hydraulic pump discharge to a minimum, reducing CO2 emissions and fuel consumption by up to 20%.

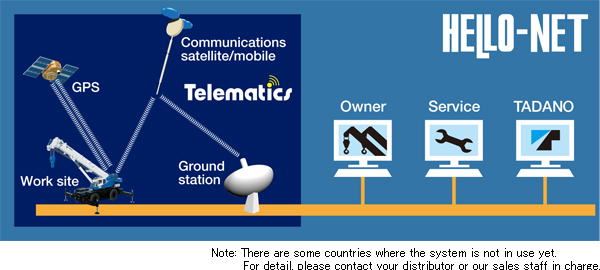

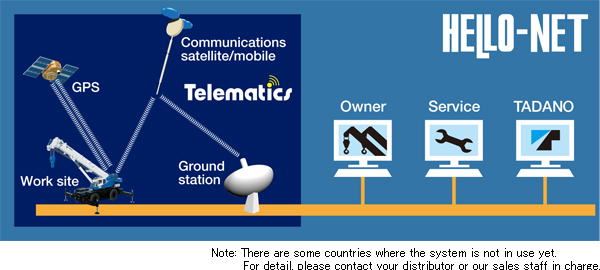

Hello-Net is a standard feature used to support our customers’ efficient crane operations straight from your computer or mobile device. The customer can monitor their crane activity, work history, machine position data, and maintenance information. Tadano offers advanced customer support with the Hello-Net system.

Crane | ||

|---|---|---|

Crane Capacity | Boom | 80t x 3.0m |

Max. Lifting Height | Boom | 47.1m |

Boom+Jib | 64.4m | |

Max. Load Radius | Boom | 40.0m |

Boom+Jib | 46.0m | |

Boom Length | 12.0m - 47.0m | |

Jib Length | 10.1m / 17.7m | |

Extension width of outriggers | Max. | 7.3m |

Mid. | 6.7m, 5.5m | |

Min. | 2.7m | |

Carrier | |

|---|---|

Engine Model | Mitsubishi 6M60 |

Max. Output | 200kW(267PS)/2,600min-1 |

Overall Length | 14,375mm |

Overall Width | 3,315mm |

Overall Height | 3,795mm |

The 5-section 47m rounded boom is made of high tensile steel, which allows for decreased boom weight as well as increased boom strength.

Tadano’s new AML-C is easy to use. It allows the operator to simultaneously monitor: boom angle, boom length, operating pressure of elevating cylinder, the extended width of the outriggers, slewing position, rated lifting capacity and present hook weight. All of this enables the AML-C to move easily through lifting capacity changes without changing configurations and codes to make a lift.

When operating the crane with the asymmetric outriggers extended, the AML-C automatically detects the extension width of outriggers at the front and rear, and to the left and right of the crane to offer maximum work value through each area. When slewing the boom from the longer outrigger area to the shorter outrigger area, the AML-C automatically detects the motion and displays the maximum capacity depending on each extension width of the outriggers, and brings the motion to a slow stop before it reaches the limits of the allowed capacity. Therefore, even if the operator operates the crane without being aware of a change in the capacity, the AML-C monitors it continuously to ensure safe operation.

The system constantly monitors and displays on the AML screen information on fuel consuming conditions. Checking the indicator enables you to prevent wasteful acceleration and wasteful standby.

The system controls the maximum engine speed during crane operation. In addition, due to curbing an unnecessary rise in the engine speed that occurs when accelerated to excess, the system enables CO2 emissions and fuel consumption to decrease by max. 22% with the Eco mode 1 employed, and max. 30% when the Eco mode 2 is applied. In addition, it realizes a low level of noise.

The system effectively controls the quantity of hydraulic pump discharge at the time of crane operation in response to the amount of movement applied by the operating lever. Additionally, it keeps the quantity of hydraulic pump discharge to a minimum, reducing CO2 emissions and fuel consumption by up to 20%.

Hello-Net is a standard feature used to support our customers’ efficient crane operations straight from your computer or mobile device. The customer can monitor their crane activity, work history, machine position data, and maintenance information. Tadano offers advanced customer support with the Hello-Net system.

Crane | ||

|---|---|---|

Crane Capacity | Boom | 80t x 3.0m |

Max. Lifting Height | Boom | 47.1m |

Boom+Jib | 64.4m | |

Max. Load Radius | Boom | 40.0m |

Boom+Jib | 46.0m | |

Boom Length | 12.0m - 47.0m | |

Jib Length | 10.1m / 17.7m | |

Extension width of outriggers | Max. | 7.3m |

Mid. | 6.7m, 5.5m | |

Min. | 2.7m | |

Carrier | |

|---|---|

Engine Model | Mitsubishi 6M60 |

Max. Output | 200kW(267PS)/2,600min-1 |

Overall Length | 14,375mm |

Overall Width | 3,315mm |

Overall Height | 3,795mm |

Find More options